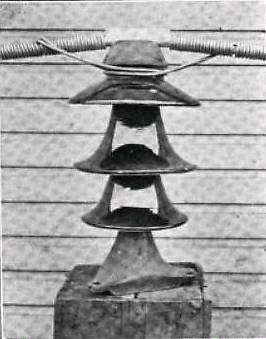

M-3890A Tie Wire Detail

By Shaun Rl; posted January 21, 2014

View Original: Click to zoom, then click to magnify (266 x 339) 265KB

|

Thomas M-3890 showing special application tie wire. For those of you interested in the history of power-line transmission development, the Niagara, Lockport, and Ontario Power Co. story is pivotal in the development and understanding of what a modern transmission system should consist of. The mainline conductor was all aluminum and had a diameter of 1.74 inches! This conductor was HUGE! They needed this big conductor to facilitate high amperage and minimize voltage loss throughout their system. The tie wire was probably #1 aluminum and I recall an account of an old lineman who remembers taking parts of this system down in the 1970s that the tie wire was the size of a pencil. The lineman would wrap the aluminum conductor with sheet metal on the parts that touched the top groove to protect the conductor from rubbing and also minimize the damage from an power arc. Also, the tie was designed to not cut into the conductor if an excessive amount of strain was placed on it. It was designed as a "Chinese Finger" and would increase it's grip as the conductor pulled from either direction. |